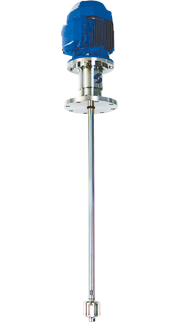

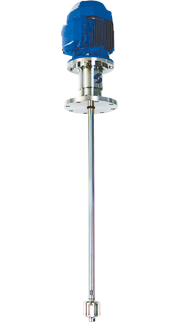

Ultramix Mixers

The Silverson Ultramix is designed for applications that are beyond the capabilities of a conventional agitator or stirrer but do not necessarily require the intense high shear of a Silverson rotor/stator mixer.

Ultramix Mixer Advantages:

Ultra sanitary design - single-shaft, single-piece mixing head.

The Ultramix series is designed for clean-in-place (CIP) with sterilize-in-place (SIP) as an option.

Full compliance with 3A TPV (Third Party Verification), USDA and cGMP requirements.

Excellent in-tank movement is provided by the dynamic mixing head, even when processing high viscosity mixes.

The powerful vortex can rapidly incorporate large volumes of powders.

Low maintenance - the single-piece mixing head is of a simple, robust construction with no wearing parts or bushings.

The design is suitable for applications from aggressive chemical service to the most demanding sanitary standards and requirements.

Ultramix

Ideal for rapidly wetting out powders including gums and thickeners, the Ultramix is also ideal for use in vessels with narrow openings. The vigorous mixing action is capable of moving the entire contents of vessels even in difficult shaped containers. For this reason the Ultramix offers considerable advantages for customers using IBCs (tote bins).

Laboratory Scale Unit

The Ultramix laboratory assembly is designed for use with the Silverson L5 Series Laboratory mixers, allowing the user to replicate the mixing characteristics of production scale Ultramix units in the laboratory.

The Ultramix is ideal for use in narrow necked containers, and provides excellent product circulation, allowing the laboratory model to mix volumes of up to 12 liters (depending on product viscosity).

Ultramix Mixers - How It Works

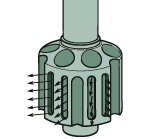

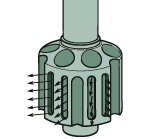

Stage 1

As the mixer rotates at high speed, the grooves on the outside of the dynamic mixing head project the surrounding product outwards with great force, creating an area of low pressure around the trailing edge of each groove.

Stage 2

This draws product from within the mixing head, through the radial slots to the outside, subjecting the material to a shearing action. The grooves in the head drive the product outwards into the body of the mix at high velocity.

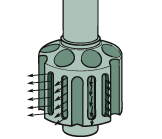

Stage 3

As material is drawn out of the slots, fresh material is sucked in through the holes in the top and bottom of the mixing head; this material is then drawn out through the slots and projected back into the mix. The pumping effect of the grooves and the shear action of the radial slots ensures rapid mixing, and develops a vigorous axial flow pattern throughout the vessel.

Ultramix Mixers - Technical Information

Capacity

5 - 2000 gallons.

Materials of Construction

All wetted parts in 316L stainless steel. Special material on request.

Motor Specification

TEFC, washdown duty and explosion proof motors are available as standard.

Mounting

Stainless steel flange fitting is available as standard.

Sealing

V-ring shaft seal as standard.

Cleaning

Clean-In-Place (CIP) design. Simple, easy-to-clean construction.