All-round labelling with hot glue, in particular for PET-bottles – cost-effective and logical.

Labelling machines with unmistakable performance.

This fully automatic labelling machine was specially developed for economical wrap around labelling of glass, plastic and metal containers of various shapes and forms.

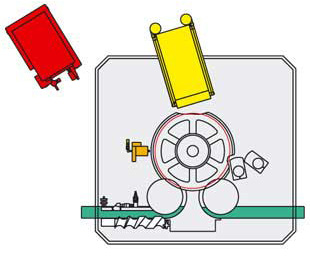

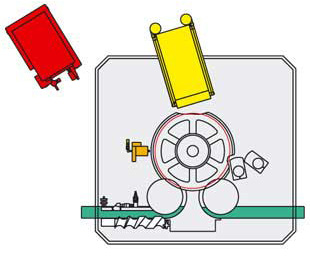

Wrap around labelling with pre-cut paper or plastic labels works without the involvement of a gluing drum. The hot melt is applied economically as spots onto the container through high pressure nozzles and the container takes the label directly from the magazine.

The final gluing is by a continuous vertical glueoff strip. Using this economical and clean gluing method means we save not only on change parts and components but also minimise the daily cleaning requirements.

Operation – precise and user friendly: The ROLLINA is very easy to use. The machine works continuously with easy handling and a minimum of operating costs. Changeover to other containers and label formats is quick. The closed hot melt system is absolutely low maintenance. The ROLLINA is complete with transparent, attractively shaped guarding and meets the highest accident prevention standards.

Easy changeover: The ROLLINA provides for exceptionally quick changeover to other bottle sizes. Apart from the guiding parts, there is only a timing belt pulley to change for another container diameter. The initial gluing is adjusted by a simple 2 way setting.

Speed range: 20 to 700 per minute. The labelling machines are customer driven solutions adapted to the speed and size. Hence we produce small and compact machines for lower speeds right up to high performance machines over a whole range of equipment configurations.

Labels: • Pre-cut paper labels • Pre-cut film labels

Containers: Glass, plastic, metal and molded containers

Gluing system: Hot glue

Benefits

•High machine reliability using brand name components for drive and control

•Carousel-type construction for accurate bottle guidance

•Space saving, compact construction

•Tried and tested premium technology hot glue labelling

•Comprehensive safety systems

Available features

Precise rolling

The turning of the bottle plate of the ROLLINA is for cylindrical containers via a precision drive belt. The label is pulled taught by the turning action, and then securely attached by way of the final glue strip.

When processing molded containers, the turning of the bottle plate is operated by way of special control pad system that provides a specific turn for the molded container.

Servicing a breeze

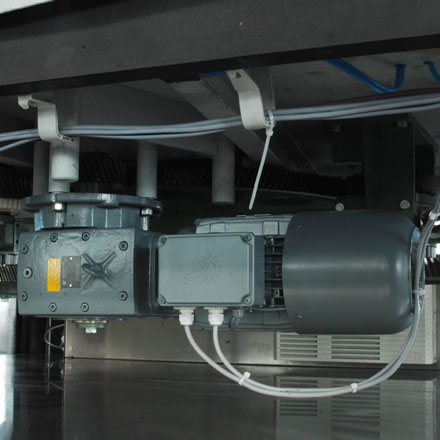

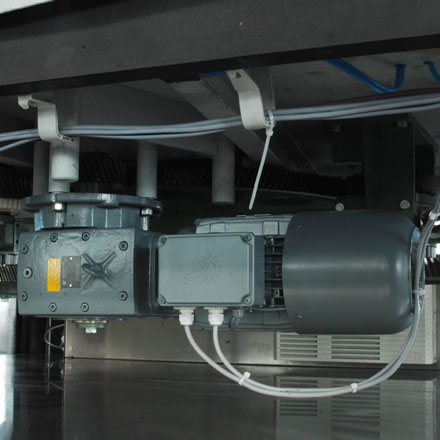

The complete electrical system for the drive, servo motors, photoelectric controls and camera system is clean and easy to maintain and is integrated into the machine base. Separate space-consuming control cabinets are not required.

Drive and Control

The drive is a frequency-controlled three phase AC motor.

The integrated PLC not only ensures a reliable mode of operation, but it also opens up the possibility of readily upgrading with various additional attachments.

Multiple Configurations

The modular design of the machine means that the carousel can be of different diameters to suit the speed required.

For lower speeds the carousel can be extremely compact.