Full Automatic Food Packing Unit Introduction and Features

The full automatic food packing unit is used to package kinds of snack food, it can realize whole process automation from weighing and filling to bag making and packaging.

1.The unit consists of PLC, Servo drive system, Pneumatic control system and man-machine interface touch screen, which can accomplish multiple functions like counting, date printing, nitrogen charging (gas discharge), finished product conveying, etc.

2. Intelligent temperature controller, high accurate, sealing is nice, firm and flat

3. The setting and modification of packing parameter can be carried out by touch screen, it can store 10 different product packing parameters, when replace product can be used at anytime, no need to reset

4. This full automatic food packaging unit can make pillow bag, corner folded bag, perforated bag and multiple continuous bags according the customer's need.

5. Employ optical fiber identification signal transmission and the encoder to confirm function, higher precision.

Full Automatic Food Packing Unit Working Procedure

The full automatic food packing unit consists of Z type elevator, multi-head combination weigher, vertical packing machine, supporting platform, product conveyor, Nitrogen-Generators, air compressor, the working process of it is as follow:

Materials--lifting and conveying--storage bin--weighing and filling--packing, sealing and molding--finished product conveying--counting and packaging in box

Full Automatic Food Packaging Unit Application

Full automatic food packaging unit is suitable for packing melon seeds, almonds, pistachios, pine nuts, candy, jelly, beans, quick frozen food, pet food and other kinds of leisure food.

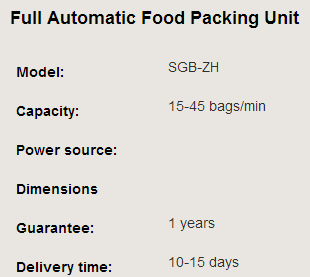

Technical Parameters of Full Automatic Food Packing Unit Parts

1. Z type elevator

1) smooth feeding, no broken of material

2) the shell is made of stainless steel or carbon steel surface spraying plastic, tipping bucket is made of engineering plastics

3) lifting capacity≥2T/h

2. SGJ-ZH multi-head combination weigher

1) full stainless steel material 2) weighing range:10g-5000g 3)weighing accuary:±0.1-2g 4)weighing speed:30-70 bags/min

3. SGB vertical packaging machine

1) driving method: Pneumatic and servo motor 2)operation interface: LED

3) controller: PLC 4)signal transmission: optical fiber

5) heating method: temperature controller 6)sealing method: constant temperature thermal sealing

7) sealing type: fine tooth strip lines or knurling pattern

8) incision format: zigzag or flat incision 9)date printing: coding machine

10) bag making: kinds of shapes such as pillow bag, head bag, hanging bag, etc

11) bag material: PE+PET composite film 12) bag size:50-490*80-375mm(L×W)

13) noise≦60Pa 14)packing range:15-45 bags/min

4. Supporting platform: made of carbon steel surface spraying plastic, 2.4*2.4*1.9m (L*W*H)

5. Finished product conveyor: pimp or scraper conveyor

6. Nitrogen -Generators: Nitrogen source should supply by customer

7. Air compressor: Air pressure (0.6 Mpa)