Built by Craftsmen. Designed for Efficiency. Constructed to Last.

Last year, Anderson Dahlen acquired the Checker spiral steam oven business with the idea of combining it with their own linear steamers and expanding the total product offering. Along with that purchase Anderson Dahlen added several key Checker design, sales and manufacturing people to their staff to assist them in their new endeavor.

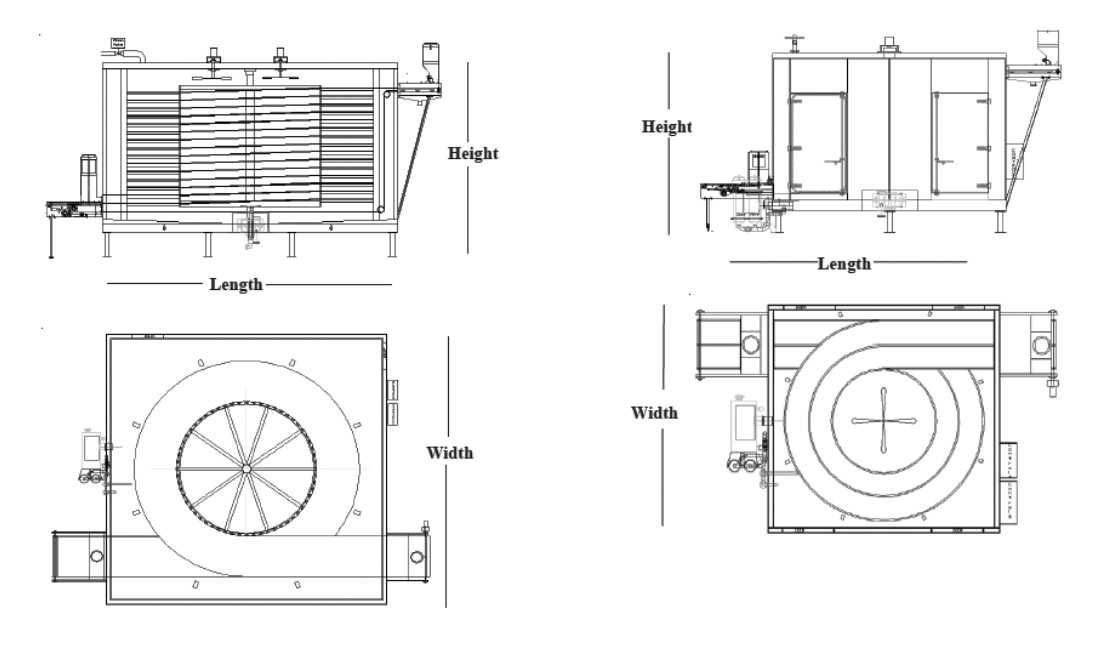

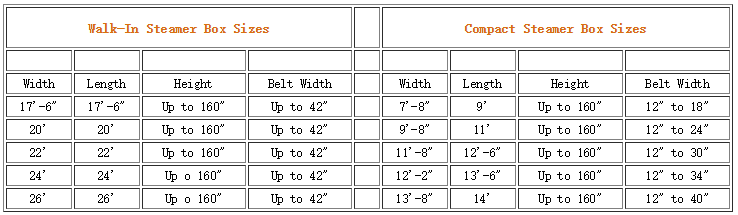

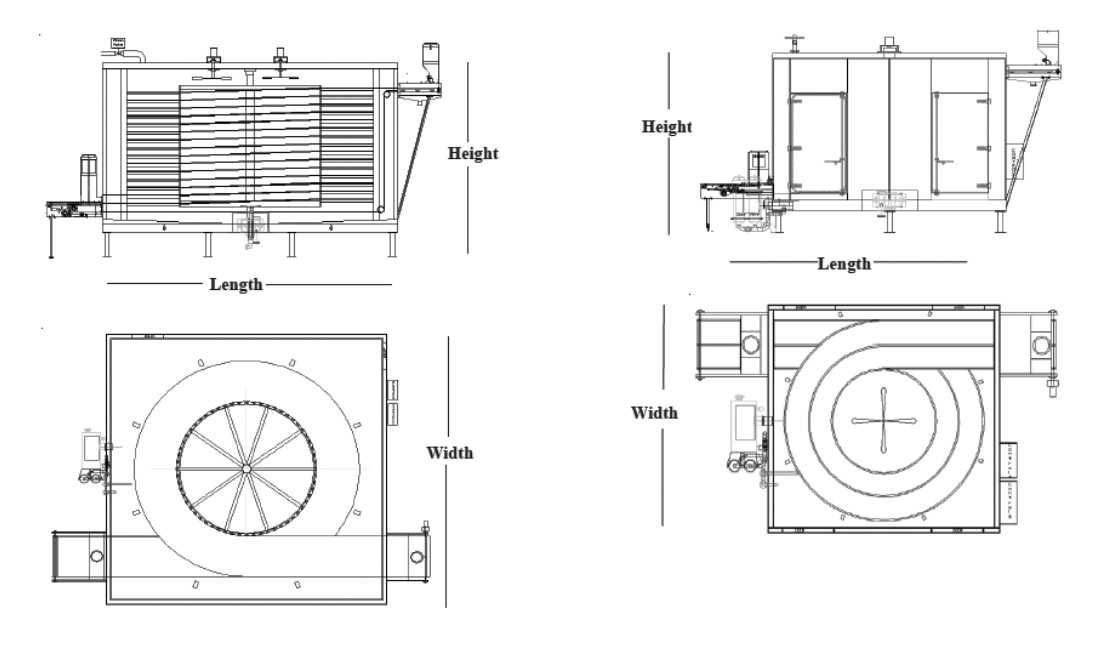

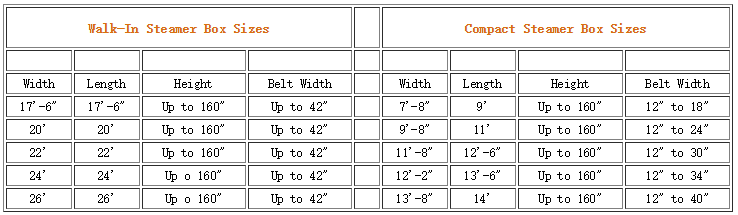

These ovens cook their product by means of direct steam injection into a containment chamber that houses several tiers of low-tension spiral conveyor belt. The product line consists of small compact units for short dwell time requirements and large walk-in units for longer cooking requirements. Multiple belt widths and radii provide a large number of possible configurations with cooking capacities ranging from 1,000 lbs. per hour to in excess of 20,000 lbs. per hour. Combining Spiral steam oven cooking with linear steam oven cooking makes continuous process steaming of any product our specialty.

Checker Spiral Steam Oven Advantages & Benefits

Designed for Efficiency, Flexibility, Reliability and High Yield Output

Checker Spiral steam ovens cook by direct injection of saturated steam into the spiral oven cooking chamber These ovens cook their product by means of direct steam injection into a containment chamber that houses several tiers of low-tension spiral conveyor belt. The product line consists of small compact units for short dwell time requirements and large walk-in units for longer cooking requirements. Multiple belt widths and radii provide a large number of possible configurations with cooking capacities ranging from 1,000 lbs. per hour to in excess of 20,000 lbs. per hour.

Higher yields - Enhanced flavors

Checker Spiral steam ovens deliver a higher yield on most products because of the gentle nature of steam cooking. Steam is an extremely efficient heat transfer medium so cook times are reduced and moisture is retained producing higher yields. Product flavor in many cases is enhanced due to the self-basting nature of spiral cooking – each tier drips fat onto the tier below.

Large capacities from relatively small ovens

Checker Spiral steam ovens require less plant space for cooking needs than any other type of cooker.

Flexibility

Checker Steamers are used to cook chicken, turkey, beef, pork and fish and other sea foods as well as eggs, dumplings, pot stickers, surimi, meatballs, sausage, and crumbles. Whether whole muscle, sliced, diced, pulled or stuffed, anything that will cook in a steam environment will cook in a Checker spiral steam oven. Our ovens all also used for post package pasteurization and/or complete cooking of packaged products.

Designed specifically for cooking

Checker spiral steam ovens are designed from the ground up to be high yield steam cookers, some competitors attempt to convert spiral freezer designs for steam cooking which is less than optimal.

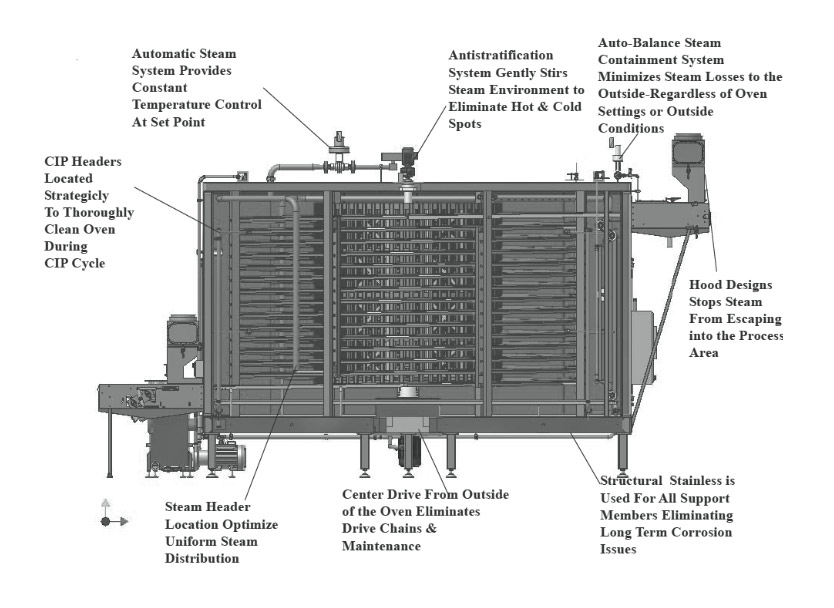

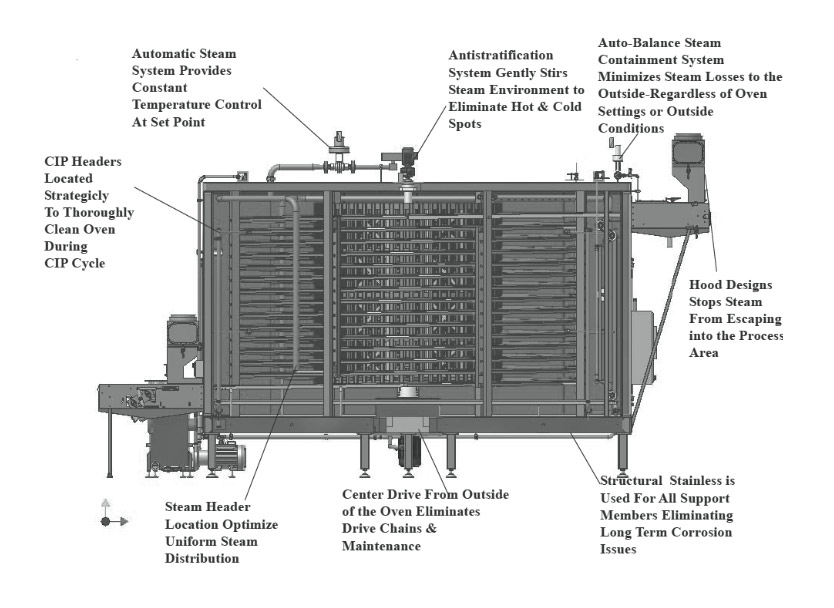

Unique center cage direct drive, electric or hydraulic

We offer both electric and hydraulic direct drive systems providing trouble-free operation – no drive chains to maintain. Tension drive is also a low-maintenance direct drive.

Variable belt speeds from 5-70 FPM

Wide range of cook times available giving you the maximum flexibility for different products – all our machine have a 10-1 turn down drive range. Our spiral ovens utilize Low-tension spiral belt systems. This proven reliable and flexible design has been around for 50 years and is well understood.

Checker Spiral Steam Ovens Specs

Checker Spiral Oven Specifications & Common Configurations

Fully welded 304L/316L stainless steel construction

All materials even the structural components are fabricated 304L or 316L Stainless Steel– no carbon steel is used in the manufacture of our ovens. All internal bearings are stainless steel as well. Our machines normally have a 20-year plus useful life when properly maintained.

Oven is pre-wired and tested in the factory

Checker Steam Ovens are fully pre-wired and tested our facility prior to shipment, simplifying installation and reducing installation time.

Low maintenance costs

Since our ovens are steamers, we use a special grade of low-cost UHMW wear material on the cage wear caps and under the belt. We, along with UHMW suppliers, have developed a High Temp/High Chemical resistant UHMW which gives us superior wear material life. Liberal use of expansion joint and floating wear material keep Checker Steamers running with little down time. Typical Checker Steamer maintenance costs (including belt amortization costs) are between $5 and $10 per operating hour compared to $50-$100/hour for high temperature ovens. Most Checker Steamers log over 6,000 run hours per year.

Advanced automatic controls

Allen Bradley touch screen and PLC provide for a simple operating environment –the touch screen is ICON-driven and easy to learn and understand. Operating controls can be password protected to keep unauthorized adjustments being made to the process. Controls can be fully integrated on the company network allowing multiple view/control locations on any customer networked computers, iPhones or android devices. This networked capability means that the machines operating software can also be programmed and monitored from remote locations which allow for upgrades and troubleshooting to be done without a plant visit. All electronics are housed in NEMA 4x rated enclosures and the main control panel is also covered with a Lexan safety cover, lessening the possibility of screen damage and down time.

Fully automatic steam control system

You need only set the temperature you require in the oven. Our Steam control system and Auto-balance steam containment system controlled by the PLC maintains the temperature you set.

Steam lock on discharge conveyor

Our proprietary steam containment system lessens steam loss at the exit conveyor opening by 50% to 75%, resulting in lower energy costs.

Anti-stratification system in cook chamber

Unique and simple steam stirring system keeps the cook chamber temperature within 2 degrees F. of your set-point throughout the entire cooking chamber. The uniformity of temperature throughout the steam chamber allows for extremely consistent cook results.

Computer-controlled CIP (Clean In Place)

Our fully integrated CIP Oven cleaning system minimizes the need for manual cleaning of the oven interior which reduces down time and reduces cleaning chemical costs.