DRYING FILTER PRESS

Turnkey Projects Installations

Impressive advantages

Reduces operation and transport costs drastically

Produces Class A Biosolids from liquid sludge in a safe and enclosed environment without the need for additional dewatering equipment

Operates with minimal supervision due to its high level of automation

Generates no noise or odor disturbances in the neighborhood

Operates on various low temperature heat sources, such as steam, hot water or thermal fluids

Requires minimal space

Drying Filter Press

Reliable equipment – Useful and ecological end product

Ideal for the wastewaters generated by the rinsing process at slaughterhouses and food transformation plants, for recoveries from the filtration of pigments, fumes and particles in mining or metallurgical transformation plants

Dries municipal and industrial sludge and produces cakes reusable as fertilizers, fuels or inert aggregate material

Huge reduction of inconveniences to the neighborhood due to transport noise and dust

Economical and ecological replacement option to landfills

Net GHG reduction when producing fertilizing biosolids

Superior results

At the VfA Verein für Abfallentsorgung plant (VfA Association for Waste Disposal) in Buchs, Switzerland, a filter press dryer is in operation to dewater and dry the sludge from the flue gas desulphurization process of a waste incineration plant. The press is built with 59 PP membrane plates of 1200 mm in size and produces 300 dry metric tons per year of cake at 70% solids content. It operates at a rate of 3 cycles on each 24 hour day, with very minimal supervision.

Drying Filter Press - Superior Results

DRYING FILTER PRESS

Plate size: 470/630/800/1000/1200/1500 mm

Cake thickness: 25/32/40 mm

Worldwide references

More than 50 Berlie Technologies Inc. systems are now in operation worldwide.

Advanced technology

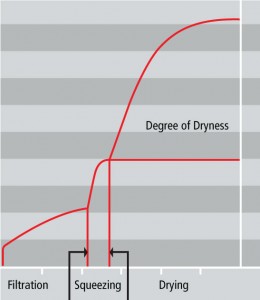

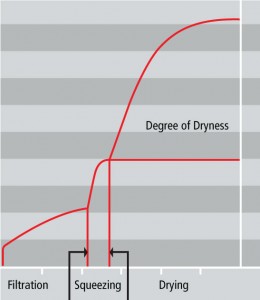

In our Patented Filter Press Dryer, sludge enters at 2% to 6% in solids content and is dried to a solid cake of up to 99% in solids content.

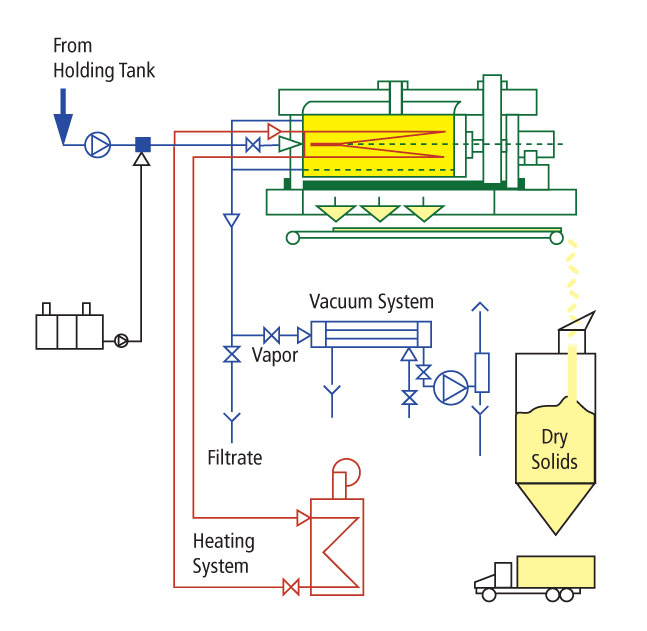

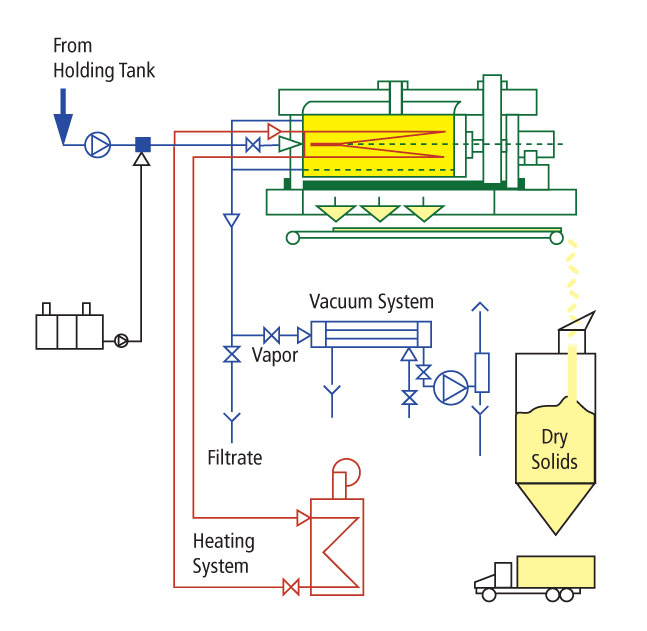

System configuration

Performance chart

Energy savings and recovery

When processing liquid sludge, this drying system can be operated without additional purchase of fossil fuels if steam, hot water or thermal fluids are available as recovered heat sources.

When processing digested sludge, this drying system can be operated without the purchase of fossil fuels if the digestion biogas is recycled as an efficient heat source to generate steam, hot water or thermal fluids.