Built to cGMP requirements

Industry standard non-proprietary components

12” thick intake and exhaust HEPA filters for maximum air flow

Semi-automatic and manual doors available

All-welded construction – no particles can enter

Fully automatic cycle controlled by Allen-Bradley PLC control systems

Temperature range from 50 – 400°C

Extremely reliable operation with very limited maintenance

Applications

Dry heat sterilization and depyrogenation ensures complete destruction of micro-organisms by means of dry heat over a controlled period of time. The process is environmentally safe and, therefore, ideal for treatment of empty ampoules, injection bottles, infusion bottles and production equipment. It is also suitable for sterilization of liquids with low moisture content or powder medications.

cGMP Construction

Lytzen Depyrogenation ovens are constructed completely of stainless steel inside and out. The chamber is full welded from the inside to the outside fascia panel, ensuring that no particles can migrate from the insulation into the chamber or into your clean room. All welds are visible and can be inspected. There are no hidden hollows for bacteria or particles to hide which makes the unit easy to clean.

Doors

Manual and semi-automatic door types are available for Lytzen ovens. Both door types are equipped with double gaskets sealing on two separate surfaces to ensure an extremely tight seal and enables a low surface temperature. Double door pass-through units are equipped with an interlock door system preventing operation failure and contamination through the chamber.

Guaranteed Temperature Distribution

Lytzen depyrogenation ovens utilize the forced convection principle for fast transmission of the heat to the load. Together with the shape and position of the heating element and the computer designed air distribution plates, we can achieve very tight temperature distribution across the load. The temperature distribution is tested before delivery and guaranteed without the need for adjustments once it arrives at your site.

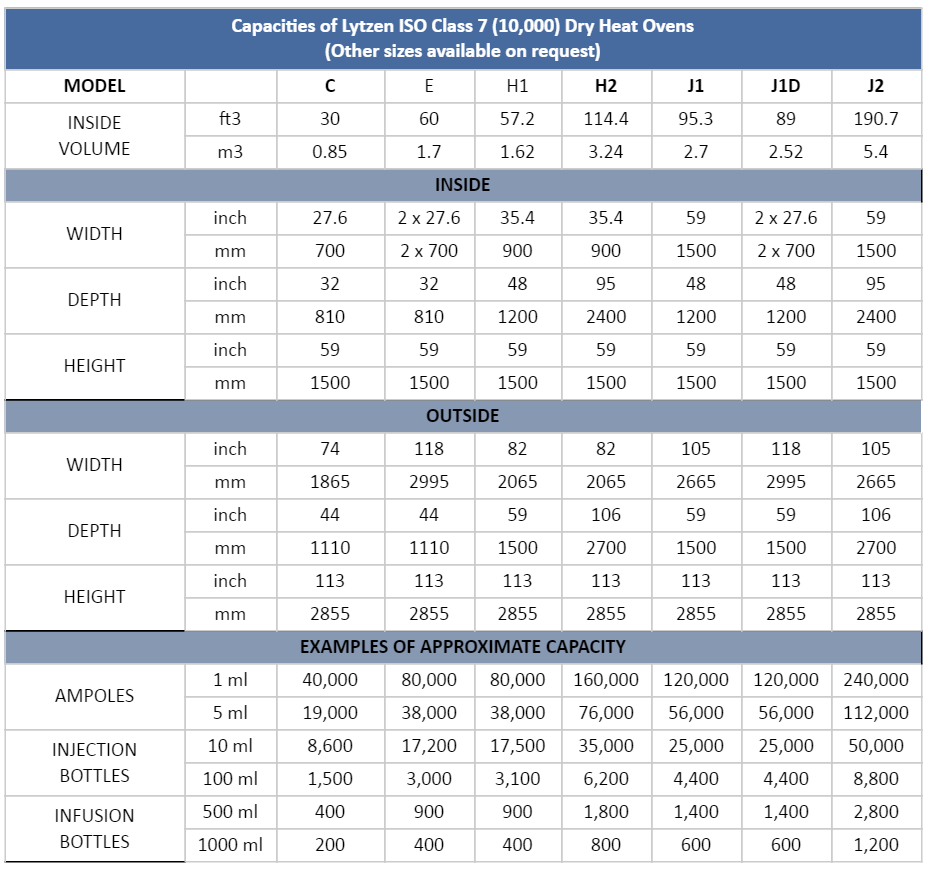

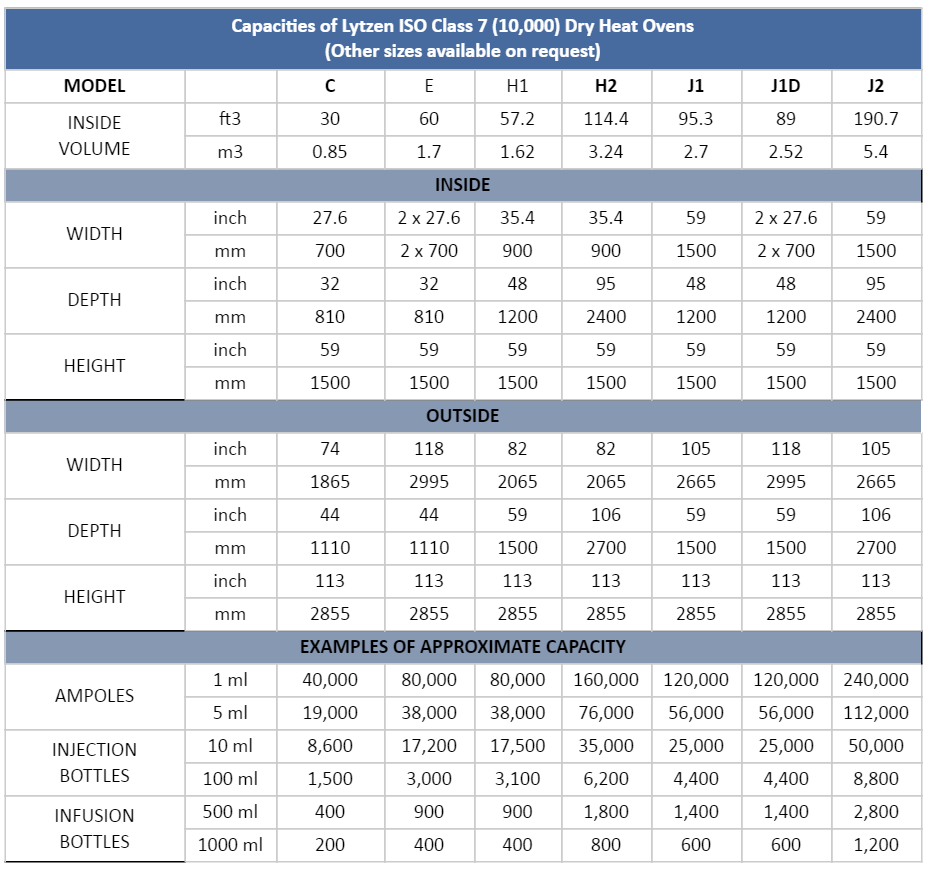

Class 10,000 (ISO Class 7)

Lytzen Class 10,000 depyrogenation ovens have HEPA filters on the air inlet and exhaust. The chamber construction and the sealing of the chamber guarantee’s Class 7 without the need for internal HEPA filters which reduces the overall investment. Lytzen Class 10,000 Dry Heat Ovens are often used for sterilization of dry product and for depyrogenation of instruments, tanks, trays, glassware and other dry goods.

Cooling

Both forced air cooling and water cooling are available for Lytzen ovens, with water cooling being the most efficient especially for larger models. Due to the unique design of Lytzen ovens, the units can be heated and cooled at full speed without the need of ramping while maintaining a very low particle count.

Energy Savings

The exhaust is equipped with a motorized damper controlling the air exchange during the cycle. The damper will be closed during the heating and sterilization step to save heat loss and energy.

Lytcon 2 Control System

The Lytcon 2 control system is designed to comply with the requirements for control of critical production. The system is available with Allen Bradley or Siemens Industrial Grade PLC and utilizes touch screen operator interfaces. The system can be delivered for storing process data on electronic media, ready to be integrated into a production complying with FDA 21 CFR, part 11.

Documentation

As the demands from the regulatory authorities have become more stringent, a high level of documentation has become a requirement. As standard, Lytzen provides the highest level of documentation which includes a comprehensive Operation and Maintenance manual together with Installation Qualification and Operational Qualification documents.

GAMP

Lytzen’s industrial grade PLC control systems are programmed utilizing the latest “Good Automated Manufacturing Practices” to ensure ease in validation of the software. As an option we will provide the GAMP documentation along with your Lytzen Depyrogenation purchase.

Accessories

The accessories are specially designed for the rigorous temperature changes inside a depyrogenation oven and the special cGMP requirements within the pharmaceutical industry. The full package of accessories includes transfer trolleys, mobile racks, wire trays and cassettes. For storage, the transfer trolleys are provided with a unique space saving feature.

Service and Parts

Each Lytzen oven is backed up with BMT USA’s highly trained service personnel and parts supply. Only high quality, non-proprietary parts that are available locally or through BMT USA are utilized. BMT’s service offices are located throughout North America for fast, efficient service response.