BH5BBL - 5 Barrel Steam Brew House5 BBL Steam Fired Brew House.

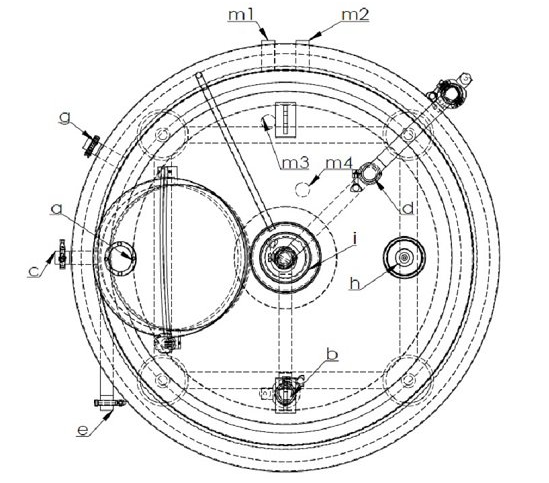

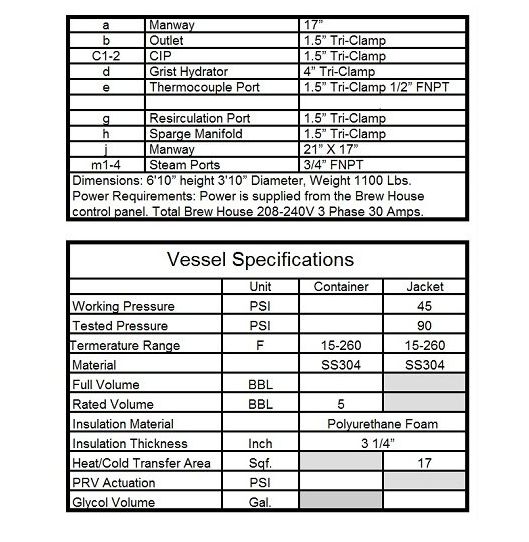

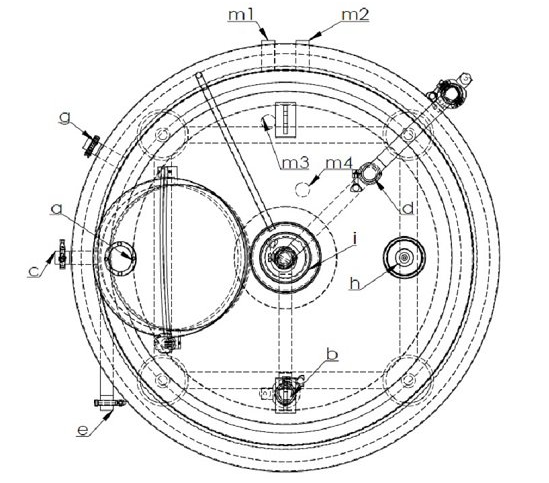

Standard 2 Vessel configuration with HLT and Heat ex-changer and 10 BBL Hot Liquor Tank. All piping(except piping for HLT to mash-tun), Mash/Lauter tun, Kettle/Whirlpool, Work platform with stairs and railing, 2-3 sanitary pumps, brew house plumbing, valves, sight-glass, heat exchanger, rakes, all vessels on steam systems jacketed, Motor, Gear box, Control Panel equipped with 3-4 VFD's, Thermocouples, PID controllers, Relays, Transformers, Grist Hydrator. Recommended steam generator size 5-7 HP. All pumps and rakes variable speed for superior fluid control.

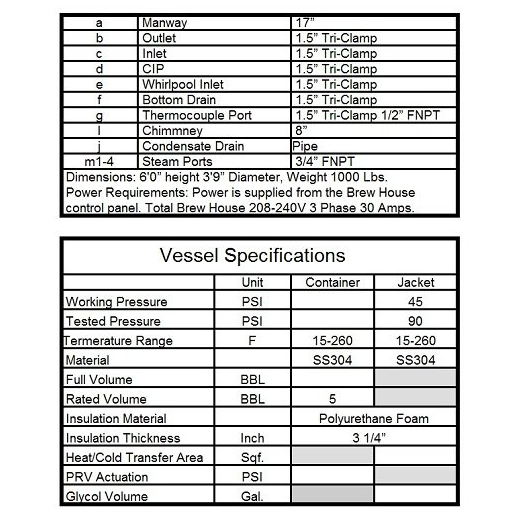

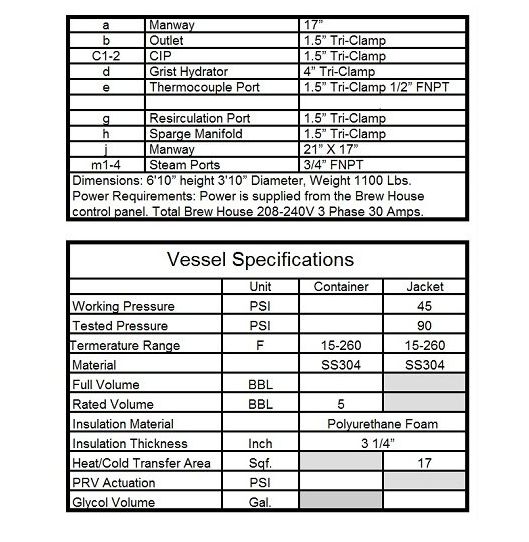

All stainless steel (304) sanitary construction 100% TIG welded and sanitary polished with quality controls, inspection and pressure testing.

Design pressure atmospheric

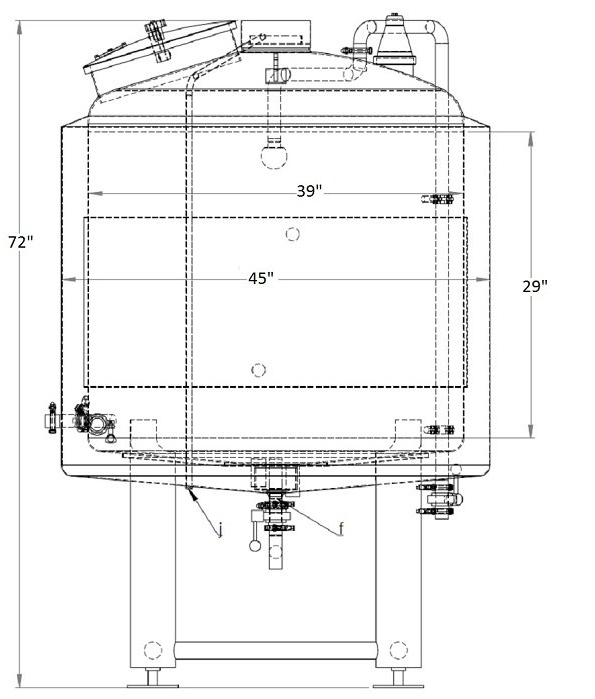

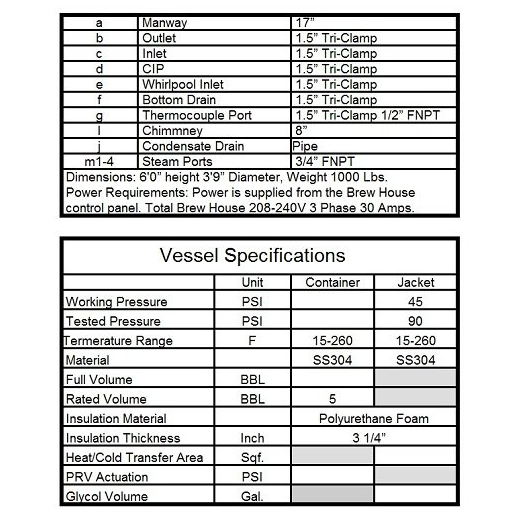

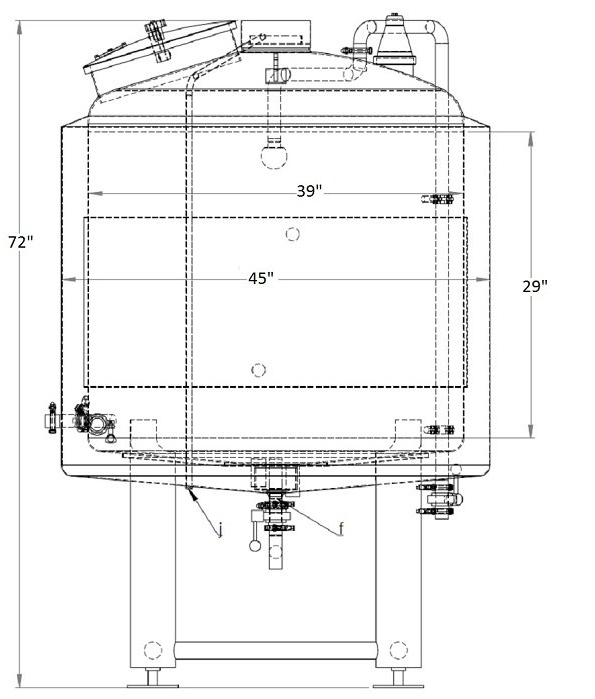

4 heavy duty stainless steel legs with self- leveling footpads

Interior shell: 304 stainless steel, thickness 11 gauge (3mm)

Exterior shell: 304 stainless steel, thickness 14 gauge (2mm)

Interior and exterior finish bright polish to 3A 240 grit, sanitary surface

Tri-clamp 1/2" FNPT for thermocouple

Top manway door

1.5" (38.1mm) Tri-clamp sanitary

Lifting Lugs

Fully welded exterior shell

Tank complete with fittings, valves and all parts

Polyurethane insulation thickness 3 1/8"(80mm) on side and bottom where applicable

8" (204mm) chimney with condensate drain Kettle only

CIP arm and single/dual spray ball(s)

Recirculation manifold on certain vessels

Steam Heat Jackets on certain vessels. All jackets Dimple type

Jacket design pressure 15PSI Test Pressure 60PSI

Mash tun

Kettle/Whirlpool