Jumag oil or gas fired steam boilers link the advantages of a compact quick steam generator with those of a robust and reliable shell boiler.

OVERVIEW

OUTPUT OF 100 KG/H UP TO 560 KG/H

OIL OR GAS FIRED WITH INDUSTRIAL BURNERS

REQUIRES NO APPROVAL IN GERMANY AND MANY OTHER COUNTRIES

ROBUST VAPORIZATION SYSTEM IN THE FORM OF A SMALL SHELL BOILER

CENTRIFUGAL PUMP INTEGRATED AS A BOILER PUMP

EASY TO USE, VERY HIGH-PERFORMING TOUCH-SCREEN CONTROLS

ADVANTAGES

ENERGY-EFFICIENT:

High heat exchange performance on a small area

High efficiencies

Condensing boiler technology (> 100% efficiency) with downstream second economiser

3- to 4-duct flue gas control

Dry steam

Energy efficient Jumag equipment for minimal losses

Combines the advantages of a large shell boiler with those of a quick steam generator

ROBUST AND LOW MAINTENANCE

Vertical vaporization system similar to a shell boiler with wall thickness up to 9mm

No pipe coil

Integrated, low-maintenance centrifugal pump

Considerable operating safety due to the simple and compact overall structure

High standard of quality, due to the use of industrial standard components

USER FRIENDLY

Simple usage via intuitive touch-screen controls in many languages

No approval needed in many countries

Easy access for maintenance

Automatic start with a timer or by an external signal

Optionally with automatic blow down or desalination

FLEXIBLE AND SIMPLE

Modular JUMAG standard components, optimally matched to one another and simple to combine

Operating pressure up to 13 bars, working pressure is 5 bars to 11 bars

Only requires small space thanks to compact design

Modular and expandable for further Jumag steam boiler

Available as compact, skid-mounted steam system including blow down vessel and water treatment unit

Available as pre-assembled container solution

FUNCTIONING

FUNCTIONING

THE BASIC EQUIPMENT

Double-walled pressure vessel similar to a small shell boiler

Low-maintenance centrifugal pump

Intuitive touch-screen controls in many languages

Integrated control cabinet

Additional safety devices above regulations: Safety valve, steam pressure limiter, exhaust temperature limiter, steam temperature limiter, low water level shut-off, pump pressure monitoring

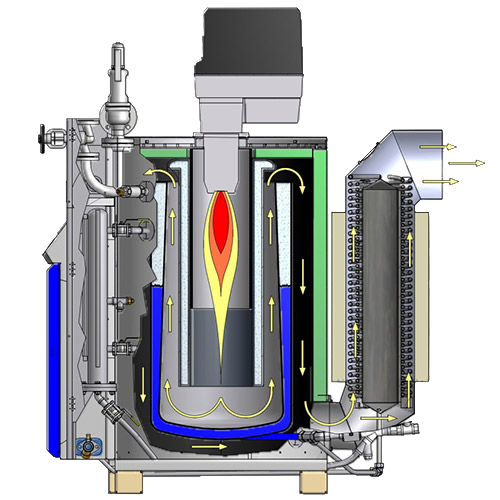

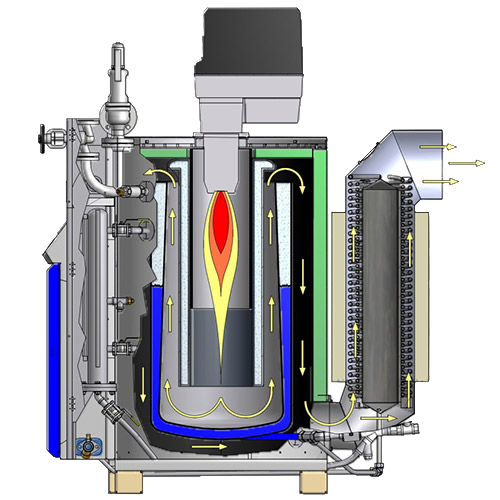

THE FUNCTIONING

Depending on the water level in the pressure vessel, the feed water is replenished by means of the boiler pump via the economiser into the pressure vessel.

The burner is controlled depending on the steam pressure. Via multiple pass flue-gas routing, the heat transfer takes place through the pressure vessel on the water.

In the economiser additional heat is transferred from the flue gas to the fresh water in a counter current. In the inner part of the pressure vessel the steam is dried.